Insulating tubes and sheaths are essential components in this area. These products are designed to protect and insulate electrical cables and components, ensuring safety, reliability and very high performance.

Discover

Insulating tubes and sheaths are essential components in this area. These products are designed to protect and insulate electrical cables and components, ensuring safety, reliability and very high performance.

Discover

HF products are components and materials designed to operate in applications involving high frequency signals. They guarantee excellent performance and are ideal for the telecommunications industry and other applications.

Discover

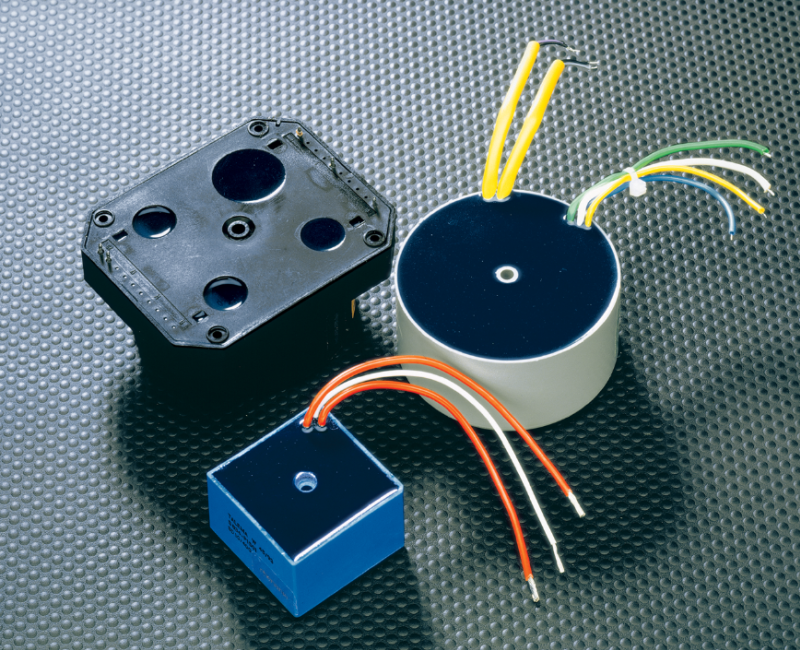

Resins casting and potting are polymeric materials used in insulating herbs to protect electrical insulators components. Casting resin is cast into molds to create precise shapes, while potting completely seals.

Discover

These electrical insulators are innovative materials designed to offer excellent performance in thermal and electrical insulation. They combine flexibility, durability and strength, making them ideal for the electromechanical applications for which they are intended.

Discover

Oil transformer insulators are crucial materials for the industry. They are used to insulate and protect the internal components of electrical transformers that use oil as a cooling and insulation medium.

Discover

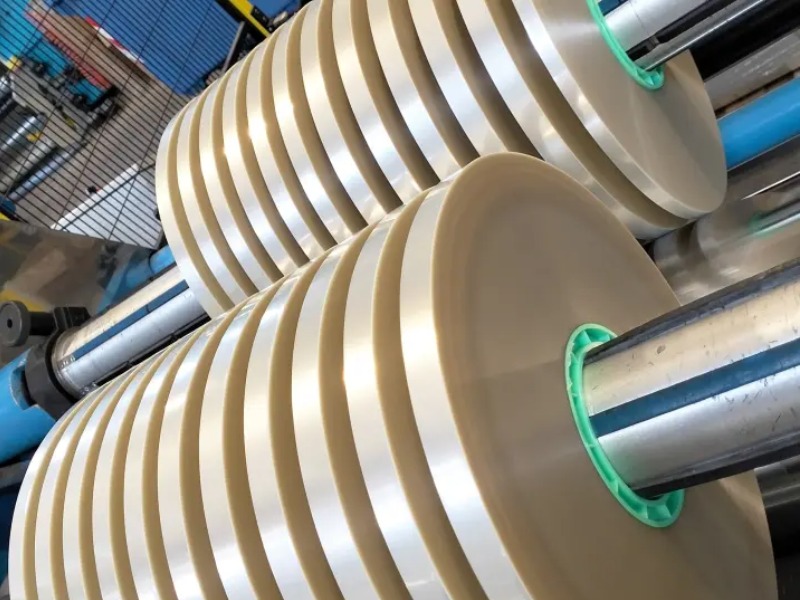

Our electrical insulation tapes, featuring non-corrosive adhesive, provide essential insulation and protection to ensure the safety and efficiency of electrical equipment in industrial and domestic applications.

Discover

From electronic circuits to automotive structures, our structural adhesives provide reliable performance, mechanical strength and durability. These features ensure that the insulation panels remain stable.

Discover

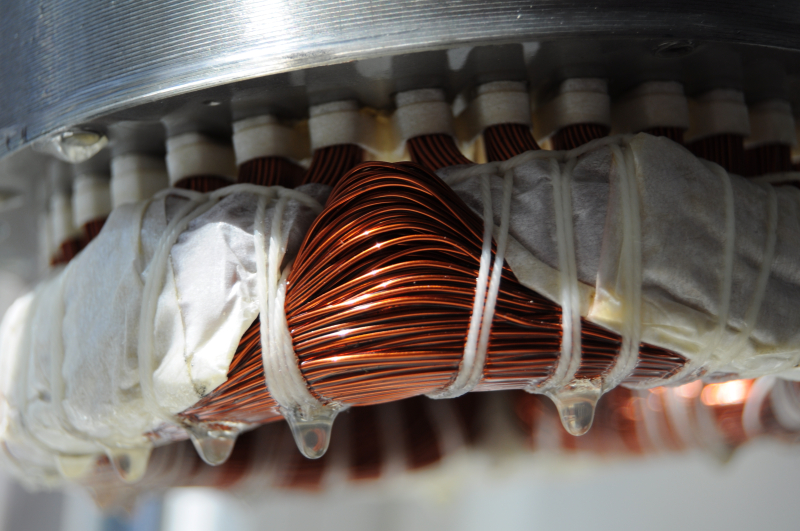

Impregnation paints and resins represent an essential category of electrical insulators, designed to ensure the protection and reliability of electronic components. They are useful for the prevention of short circuits.

Discover

Midel dielectric fluids are a safer and more environmentally friendly alternative to traditional mineral oil dielectric fluids. These offer reliable performance in a variety of high voltage electrical applications.

Discover

Rigid insulators, with excellent insulating properties, mechanical and thermal, are used in the electromechanical, electronic, railway and aeronautical sector; supplied in plates, tubes and cylinders drawn or machined to drawing.

DiscoverVia Liguria, 34/31

20068 Peschiera Borromeo (MI) Italy

MI-1030043 registration date 05/02/1980

MILAN - Number: 04653000150

Number MI021309 date 10/12/1991

©2024 Erba Isolanti srl - VAT number/tax code: 04653000150 - AUTHORIZED/SUBSCRIBED/PAID-IN share capital: euro 46,800.00 - Site created by Italia Multimedia - Web Agency Milan